Making Your Product Ideas a Reality

First we start by understanding the end goals of your project, not just the part specs. This allows us to see it from the same perspective you do, and ensures that we take real-world application into account.

Then we work closely and communicate with you throughout the production process so you feel involved and are aware of everything.

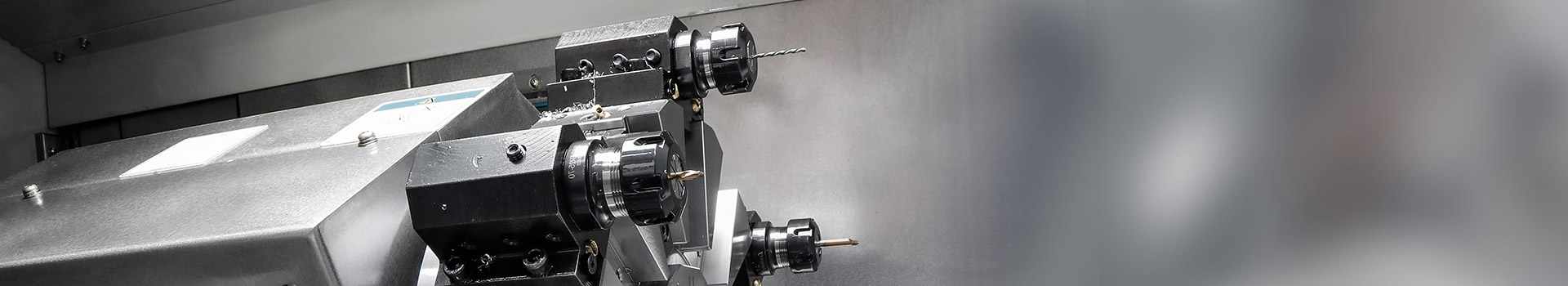

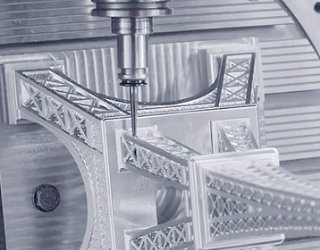

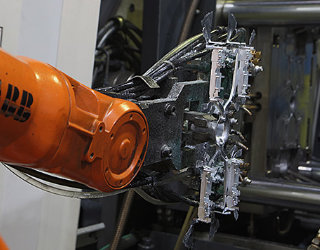

Our engineers work with you to make your product ideas a reality through manufacturing technologies like vacuum casting, CNC machining, molding and finishing services.

Years of Experience

Happy Clients

Satisfaction

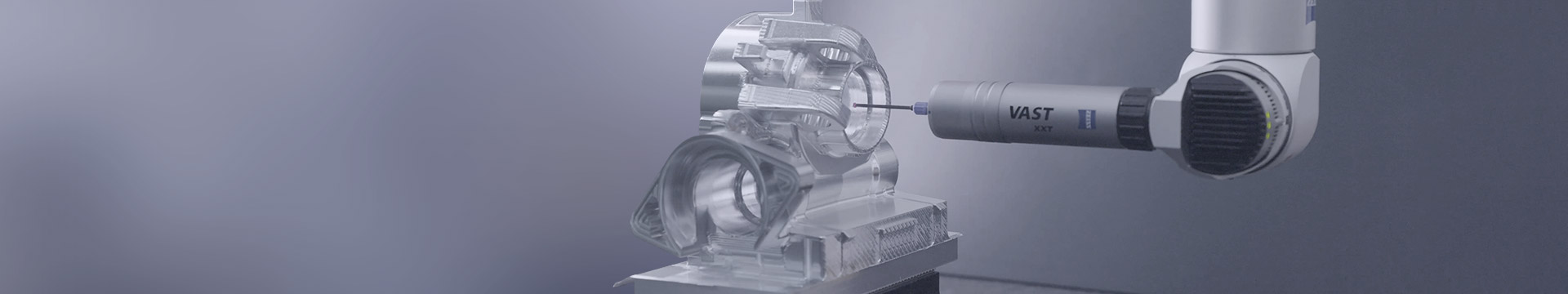

What Services We Offer For You

We have an international team of engineers and technicians as well as advanced production equipment. Turn your designs into real-life products quickly and at a great price. Your design is realized by us.

Our Components To Quality

The foundation of everything we do is our commitment to quality. From prototypes to orders in the multiple thousands, we want every finished product to exceed our customer’s expectations.

Quality is the driving force behind every item we produce. Our prototyping and low-volume production services are all subject to continuous quality control standards. They begin before your design arrives at our factory and don’t end until you are satisfied with your product.

CORE COMPETENCE

Strong Manufacturing Capabilit

Technical & Quality Assurance

Rapid Quotation & Stable Lead-time

Project Management

Latest News

Our information and promotional activities

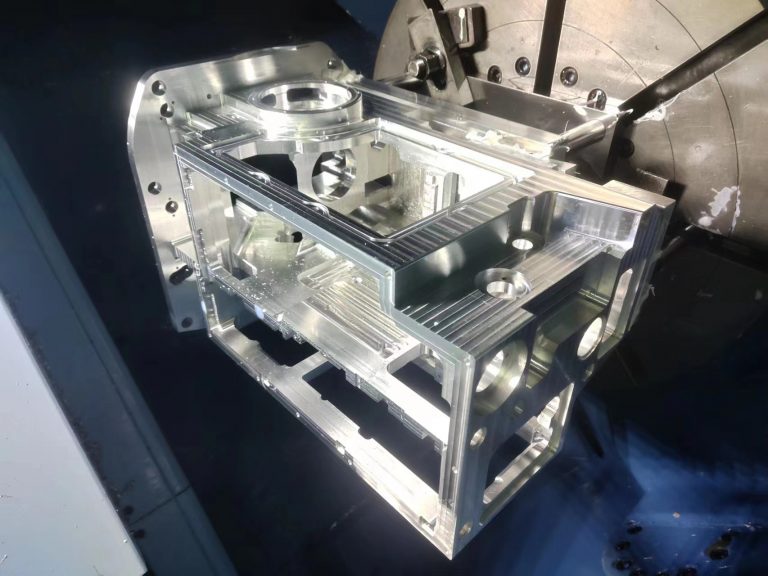

Case for CNC

A mould for

In terms of CNC machining center operation, there are many methods and techniques that can greatly improve efficiency.

I. Programming Techniques CNC machining centers require high precision in product accuracy. When programming,…

By mastering these machining techniques, you will have a solid foundation in programming

The programming of CNC machining programs is the process of writing program sheets according…

Have A Business Idea In Your Mind?

Please tell us your manufacturing requirements